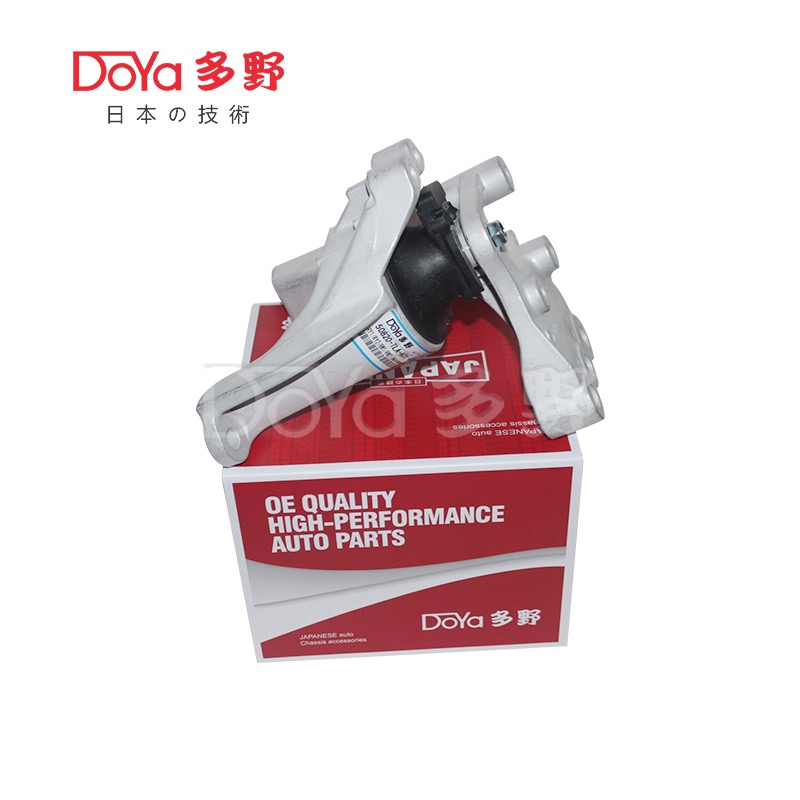

Engine Mounting

Engine mounting refers to the components and mechanisms that secure the engine to the vehicle's chassis or frame. The primary purpose of engine mounting is to support the weight of the engine and transmission, absorb vibrations and shocks generated by the engine, and isolate them from the rest o......

Send Inquiry

Product Description

Engine mounting refers to the components and mechanisms that secure the engine to the vehicle's chassis or frame. The primary purpose of engine mounting is to support the weight of the engine and transmission, absorb vibrations and shocks generated by the engine, and isolate them from the rest of the vehicle. Here are some key points regarding engine mounting:

1. Mounting Points: Engine mounting typically involves multiple points of attachment between the engine and the vehicle's chassis or frame. These mounting points are strategically located to distribute the engine's weight and maintain stability.

2. Mount Types: There are various types of engine mounts used in vehicles, including:

- Rubber Mounts: Rubber mounts are the most common type and consist of a metal bracket surrounded by a rubber material. The rubber acts as a cushion to absorb vibrations and minimize transmission of engine noise and harshness to the vehicle.

- Hydraulic Mounts: Hydraulic mounts are similar to rubber mounts but contain fluid chambers within the mount. These mounts provide additional damping capabilities, allowing for better vibration isolation.

- Active Mounts: Some modern vehicles may incorporate active engine mounts that use sensors and actuators to actively counteract engine vibrations. These mounts can adjust their stiffness or damping properties in real-time to optimize vibration isolation.

3. Functionality: Engine mounts serve several important functions:

- Support: Engine mounts support the weight of the engine and transmission, preventing excessive movement or displacement during vehicle operation or sudden acceleration or deceleration.

- Vibration Isolation: Engine mounts absorb and dampen vibrations and shocks generated by the engine, preventing them from being transmitted to the vehicle's structure and reducing noise and vibrations experienced by occupants.

- Alignment: Engine mounts also help maintain proper alignment between the engine, transmission, and other drivetrain components, ensuring efficient power transfer and minimizing stress on other parts.

4. Materials and Construction: Engine mounts are typically constructed with a combination of metal brackets or housings and rubber or fluid-filled components. The metal parts provide structural strength and rigidity, while the rubber or fluid elements provide vibration isolation and damping properties.

5. Maintenance and Replacement: Over time, engine mounts may wear out or become damaged due to continuous exposure to engine heat, oil, and environmental factors. Worn or damaged mounts can lead to increased vibrations, engine movement, and potentially affect the performance and longevity of other components. Regular inspection and replacement of worn or faulty engine mounts are essential to ensure proper engine operation and vehicle stability.

It's important to consult the vehicle manufacturer's specifications and guidelines when selecting or replacing engine mounts. Proper installation and alignment are crucial to ensure the mounts perform their intended functions effectively. If you suspect any issues with your engine mounts, it is advisable to consult with a qualified mechanic or automotive professional for inspection, diagnosis, and replacement if necessary.